Kana isu tikashamiswa nekunyatsotariswa kwedata rehutano nema smartwatches kana kuona mavhidhiyo emarobhoti madiki achipfuura neunyanzvi nzvimbo dzakamanikana, vanhu vashoma vanoteerera kune musimboti wekutyaira kuseri kweizvi zvinoshamisa zvetekinoroji - iyo yekupedzisira micro stepper mota. Aya maturusi chaiwo, ayo anenge asingaonekwe nemaziso, ari kutyaira chinyararire shanduko yehunyanzvi.

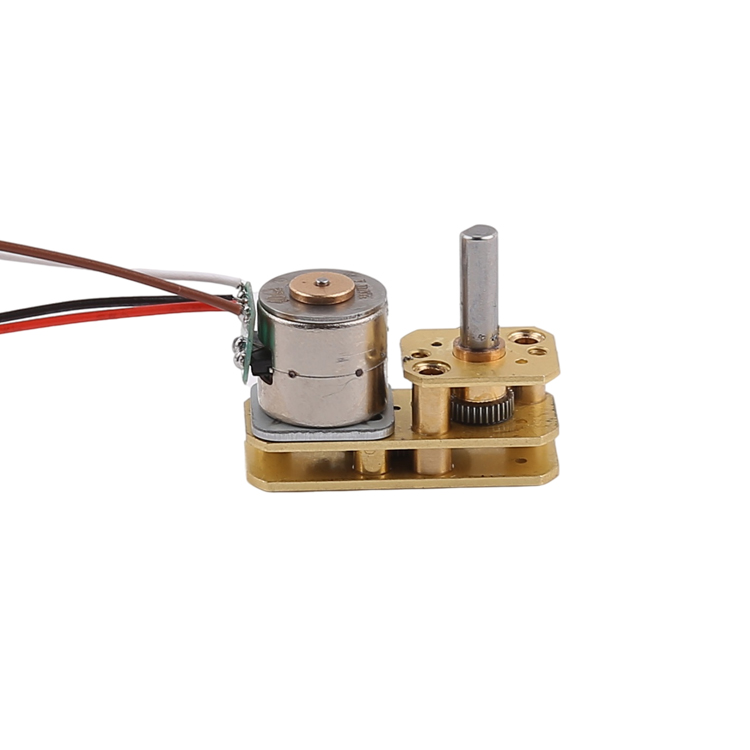

Nekudaro, mubvunzo wakakosha uri pamberi peinjiniya nemasaenzi: ndepapi chaizvo muganho weiyo micro stepper motors? Apo ukuru hunoderedzwa kusvika ku millimeter kana kunyange micrometer level, isu tinotarisana kwete chete dambudziko rekugadzira maitiro, asiwo zvipingamupinyi zvemitemo yepanyama. Ichi chinyorwa chinozoongorora kuvandudzwa kwechizvarwa chinotevera che Ultra micro stepper motors uye kuratidza kugona kwavo kukuru muminda yezvishandiso zvinopfekwa uye marobhoti madiki.

I.Kusvika kumiganhu yemuviri: matambudziko matatu makuru etekinoroji anotarisana ne Ultra miniaturization

1.Iyo Cube Paradox yeTorque Density uye Saizi

Iyo torque inobuda yemamotor echinyakare inoenderana nevhoriyamu yavo (cubic size). Kana saizi yemota yakaderedzwa kubva masendimita kusvika mamirimita, vhoriyamu yayo inoderera zvakanyanya kusvika kune rechitatu simba, uye torque inodonha zvakanyanya. Nekudaro, kudzikiswa kwemutoro wekupokana (sekukwesha) hausi kure nekukosha, zvichitungamira kupokana kwekutanga mukuita kwe Ultra miniaturization kuve kusakwanisa kwebhiza diki kudhonza mota diki.

2. Efficiency Cliff: Core Loss uye Copper Winding Dilemma

Kurasikirwa kwepakati: echinyakare silicon simbi mashiti inonetsa kugadzirisa pa Ultra micro scale, uye eddy yazvino mhedzisiro panguva ye-high-frequency operation inotungamira mukudonha kwakanyanya mukubudirira.

Copper winding limitation: Huwandu hwekutendeuka mucoil hunodzikira zvakanyanya sezvo saizi inodzikira, asi kuramba kunowedzera zvakanyanya, zvichiita kuti² R mhangura kurasikirwa chikuru kupisa sosi

Dambudziko rekubvisa kupisa: Iro vhoriyamu diki inokonzeresa yakaderera kupisa huwandu, uye kunyangwe kuwedzeredza zvishoma kunogona kukanganisa zviri padyo nemagetsi zvikamu.

3. Muedzo wekupedzisira wekugadzira kunyatsoita uye kusagadzikana

Kana iyo clearance pakati pe stator uye rotor ichidikanwa kuti idzorwe padanho re micrometer, maitiro echinyakare machining anotarisana nemipimo. Zvinhu zvisina basa munyika yakakura, senge guruva uye kushushikana kwemukati mune zvigadzirwa, zvinogona kuve mhondi dzekuita pachiyero chemicroscopic.

II.Kutyora miganho: mana ekuvandudza mafambiro echizvarwa chinotevera che Ultra micro stepper motors

1. Coreless mota tekinoroji: Taura zvakanaka kune kukuvara kwesimbi uye kumbundira kushanda zvakanaka

Kutora dhizaini yekoreless hollow mukombe, inobvisa zvachose kurasikirwa kwazvino eddy uye hysteresis mhedzisiro. Iyi mhando yemota inoshandisa isina mazino chimiro kuita:

Kunyanya kushanda zvakanaka: simba rekushandura simba rinogona kusvika pamusoro pe90%

Zero cogging mhedzisiro: yakanyanya kutsetseka kushanda, kunyatso kudzora kwega rega 'diki nhanho'

Ultra nekukurumidza mhinduro: yakanyanya kuderera rotor inertia, kutanga kumira kunogona kupedzwa mukati memilliseconds

Anomiririra mashandisirwo: haptic mhinduro motors yeakakwira-magumo smartwatches, chaiyo dhizaini masystem emapombi ekurapa anoisirwa.

2. Piezoelectric ceramic mota: tsiva "kutenderera" ne "vibration"

Kutyora zvipimo zvemisimboti yemagetsi uye kushandisa inverse piezoelectric mhedzisiro yepiezoelectric ceramics, rotor inofambiswa ne micro vibrations pa ultrasonic frequencies.

Yakapetwa kaviri torque density: Pasi peiyo vhoriyamu imwe chete, torque inogona kusvika 5-10 nguva iyo yechinyakare magetsi emagetsi mota.

Kuzvivharira kugona: inochengetedza otomatiki chinzvimbo mushure mekutadza kwesimba, ichideredza zvakanyanya standby simba rekushandisa

Yakanakisa electromagnetic kuenderana: haiburitse electromagnetic kupindira, kunyanya yakakodzera kune chaiyo zvekurapa zviridzwa

Mumiriri mashandisirwo: Precision inotarisa sisitimu ye endoscopic lenses, nanoscale chinzvimbo che chip yekuona mapuratifomu.

3. Micro electromechanical system tekinoroji: kubva "kugadzira" kusvika "kukura"

Kudhirowa pane semiconductor tekinoroji, kuveza yakazara mota system pane silicon wafer:

Batch kugadzira: inokwanisa kugadzirisa zviuru zvemotor panguva imwe chete, ichideredza zvakanyanya mutengo

Yakabatanidzwa dhizaini: Kubatanidza masensa, vatyairi, uye miviri yemota pane imwe chip

Saizi yekubudirira: kusundira mota saizi mu sub millimeter munda

Representative applications: Targeted drug delivery micro robots, yakagoverwa nharaunda yekutarisa "yakangwara huruva"

4. New Material Revolution: Kupfuura Silicon Steel uye Permanent Magnets

Amorphous simbi: yakanyanya kukwirira magineti permeability uye yakaderera simbi kurasikirwa, ichipaza nepakati pekuita sirin'i yechinyakare silicon simbi mapepa.

Kushandiswa kwezvinhu zviviri-dimensional: Graphene uye zvimwe zvinhu zvinoshandiswa kugadzira ekupedzisira-yakatetepa insulation layers uye inoshanda yekupisa kupisa nzira.

Ongororo yeYakakwira Temperature Superconductivity: Kunyangwe ichiri murabhoritari nhanho, inosheedzera mhinduro yekupedzisira ye zero kuramba mhepo.

III.Mamiriro emangwana ekushandisa: Kana miniaturization ikasangana nehungwaru

1. Iko kusingaonekwi shanduko yezvishandiso zvinopfekwa

Chizvarwa chinotevera che Ultra micro stepper motors ichave yakanyatsobatanidzwa mumachira uye zvishongedzo:

Akangwara kuonana lenses: Micro mota inodhiraivha yakavakirwa-mukati lens zoom, kuwana isina musono shanduko pakati peAR/VR uye chokwadi.

Haptic mhinduro yezvipfeko: mazana ema micro tactile mapoinzi akagoverwa mumuviri wese, kuwana realistic tactile simulation muchokwadi chaicho.

Hutano hwekutarisa chigamba: mota-inotyairwa microneedle array yekusarwadzisa yeropa glucose yekutarisa uye transdermal zvinodhaka kuendesa.

2. Swarm Intelligence yeMicro Robots

Medical nanorobots: Zviuru zvemarobhoti madiki akatakura zvinodhaka zvinonyatso tsvaga nzvimbo dzebundu pasi pekutungamirwa kwemagineti kana makemikari gradients, uye maturusi anotyairwa nemota anoita maseru ekuvhiya.

Indasitiri yekuyedza cluster: Mukati menzvimbo dzakamanikana senge injini dzendege uye chip maseketi, mapoka emarobhoti madiki anoshanda pamwechete kuendesa chaiyo-nguva yekuyedza data.

Kutsvaga uye kununura "anobhururuka svosve" system: diki inobhururuka mapapiro robhoti inotevedzera kubhururuka kwezvipembenene, ine mota diki yekudzora bapiro rega rega, kutsvaga zviratidzo zvehupenyu mumatongo.

3. Bhiriji rekubatanidzwa kwevanhu-muchina

Intelligent prosthetics: Zvigunwe zveBionic zvine akawanda emagetsi madiki akavakirwa-mukati, mubatanidzwa wega wega unodzorwa zvakasununguka, kuwana chaiyo inogadzirisa inobatika simba kubva kumazai kuenda kumakibhodhi.

Neural interface: motor-driven microelectrode array yekunyatso kudyidzana nemaneuroni muhuropi komputa interface.

IV.Maonero eramangwana: Matambudziko nemikana zvinogara

Kunyangwe tarisiro yacho ichinakidza, mugwagwa unoenda kune yakakwana Ultra micro stepper mota ichiri izere nematambudziko:

Energy bhodhoro: Kukudziridzwa kwebhatiri tekinoroji kunosara kumashure kwekumhanya kwemota miniaturization

Kubatanidzwa kweSystem: Maitiro ekubatanidza simba, kunzwa, uye kutonga munzvimbo

Batch kuyedzwa: Kunyatso ongorora kwemhando yemamiriyoni emamota madiki inoramba iri dambudziko reindasitiri

Nekudaro, kubatanidzwa kwepakati pedisciplinary kuri kusimudzira kubudirira kwezvipimo izvi. Kubatanidzwa kwakadzama kwesainzi yemidziyo, tekinoroji yesemiconductor, hungwaru hwekunyepedzera, uye dzidziso yekudzora iri kupa mukana kune yaimbove isingafungidzirwe itsva actuation mhinduro.

Mhedziso: Kupera kweminiaturization mikana isingaperi

Muganho we Ultra micro stepper motors hausi iwo magumo etekinoroji, asi nzvimbo yekutanga yekuvandudza. Kana isu tikatyora izvo zvisingakwanisi zvemuviri zvehukuru, isu tinovhura musuwo kunzvimbo nyowani dzekushandisa. Munguva pfupi iri kutevera, isu tinogona kunge tisisazvirevedze se'motor', asi se' intelligent actuation units' - vanozopfava semhasuru, senge tsinga, uye nehungwaru sehupenyu.

Kubva kumarobhoti ekurapa madiki anoendesa zvinodhaka nenzira kwayo kumidziyo yakangwara inopfekeka inobatanidza zvisina mutsindo muhupenyu hwezuva nezuva, aya asingaoneki madiki emagetsi masosi ari kuumba chinyararire mararamiro edu eramangwana. Rwendo rweminiaturization itsika yehuzivi yekuongorora maitiro ekuita mamwe mabasa nezviwanikwa zvishoma, uye miganhu yaro inongogumira nekufungidzira kwedu.

Nguva yekutumira: Oct-09-2025