Mota inodzika stepper, inozivikanwawo semota ine stepper yakatwasuka, ipfungwa yemagnetic rotor inotenderera kuburikidza nekubatana ne pulsed electromagnetic field inogadzirwa ne stator kuti igadzire kutenderera, linear stepper motor mukati memota kuti ishandure rotary motion kuita linear motion. Linear stepper motors dzinogona kuita linear motion kana linear reciprocating motion zvakananga. Kana rotary motor ikashandiswa sesimba rekushandura kuita linear motion, magiya, cam structures uye mechanisms dzakadai semabhandi kana waya zvinodiwa. Kutanga kutangwa kwe linear stepper motors kwaive muna 1968, uye mufananidzo unotevera unoratidza mamwe ma linear stepper motors akajairika.

Nheyo huru yemota dzinofambiswa nekunze

Rotor yemota ine stepper inofambiswa nekunze imagneti inogara iripo. Kana magetsi achipfuura nemu stator winding, stator winding inogadzira vector magnetic field. Simba iri remagineti rinoita kuti rotor itenderere pane imwe kona, kuitira kuti divi remagineti maviri erotor rienderane nedivi re stator's magnetic field. Kana stator's vector magnetic field ichitenderera ne angle. Rotor inotendererawo ne angle ne iyi magnetic field. Pamagetsi ese ega ega, electric rotor inotenderera ne angle imwe uye inofamba nhanho imwe mberi. Inoburitsa angular displacement inoenderana nehuwandu hwepulses input uye speed inoenderana ne pulse frequency. Kuchinja kurongeka kwe winding energization kunodzosera mota kumashure. Saka stepper motor rotation inogona kudzorwa nekudzora huwandu hwepulses, frequency uye kurongeka kwesimba re motor windings yechikamu chimwe nechimwe.

Mota inoshandisa sikuruu senzira yekubuda, uye nati yekunze inobatidzwa nesikuruu iri kunze kwemota, zvichiita kuti nati yesikuruu isatendererane, zvichiita kuti ifambise zvakananga. Mugumisiro wacho idhizaini iri nyore kwazvo inobvumira kushandiswa kwemamota ematanho anodzika zvakananga kuti afambise zvakananga mumabasa akawanda pasina kuisa chinobatanidza chekunze.

Mabhenefiti emota dzinofambiswa nekunze

Mota dze stepper dzakagadzirwa ne screw linear dzinogona kutsiva ma cylinders mumamwe maapplication, kuwana mabhenefiti akadai sekuisa panzvimbo chaiyo, kumhanya kunodzorwa, uye kunyatsorongeka. Linear screw stepper motors dzinoshandiswa mumhando dzakasiyana-siyana dzinosanganisira kugadzira, kugadzirisa nekuchenjera, kuyerwa kwemvura chaiyo, kufamba nematanho chaiwo, nedzimwe nzvimbo dzakawanda dzine zvinodiwa neunyanzvi hwepamusoro.

▲Kunyatsorongeka kwepamusoro, kugona kudzokororwa kwekuisa nzvimbo kusvika ± 0.01mm

Mota yekukwira screw ine linear inoderedza dambudziko rekunonoka kwe interpolation nekuda kwenzira iri nyore yekutumira, kunyatso tarisa, kudzokorora uye kunyatso tarisa. Zviri nyore kuita kupfuura "rotary motor + screw". Kunyatso tarisa screw yakajairika yemota yekukwira screw ine linear kunogona kusvika ±0.05mm, uye kunyatso tarisa bhora kunogona kusvika ±0.01mm.

▲ Kumhanya kwakanyanya, kusvika 300m/min

Kumhanya kwemota inokwira screw stepping ine 300m/min uye kumhanyisa kuri 10g, nepo kumhanya kwescrew bhora kuri 120m/min uye kumhanyisa kuri 1.5g. Uye kumhanya kwemota inokwira screw stepping ine screw stepping kuchawedzerwa mushure mekugadzirisa dambudziko rekupisa zvinobudirira, nepo "kumhanya kwe"servo motor & ball screw" kwakaganhurirwa mukumhanya, asi zvakaoma kuvandudza zvakanyanya.

Hupenyu hwepamusoro uye kugadzirisa kuri nyore

Mota yeLinear Screw Steping Mota yakakodzera kunyatsoshanda zvakanaka nekuti hapana kubatana pakati pezvikamu zvinofamba nezvikamu zvakagadzika nekuda kwemukana wekuisa uye hapana kusakara nekuda kwekufamba kwezvinofamba nekukurumidza. Screw yebhora haigone kuvimbisa kururama kwekufamba kwezvinofamba nekukurumidza, uye kukweshana kwekukurumidza kuchaita kuti screw nut iparare, izvo zvinokanganisa kururama kwekufamba uye hazvigone kugutsa kudiwa kwekugadzirisa kwakanyanya.

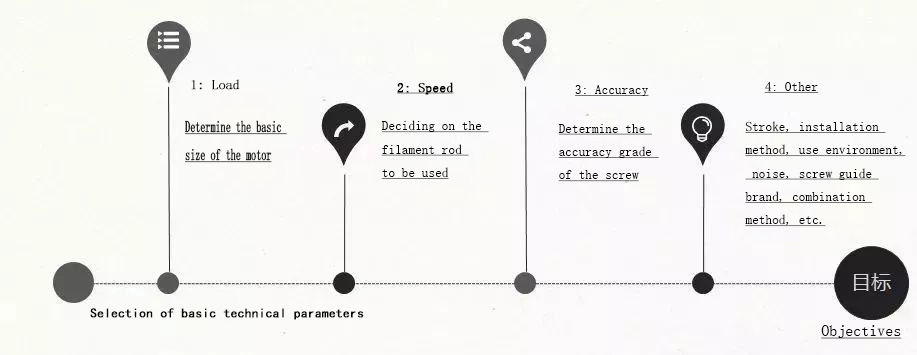

Kusarudzwa kwemota yemotokari yekunze ine mutsara

Pakugadzira zvigadzirwa kana mhinduro dzine chekuita nekufamba kwemutsetse, tinokurudzira mainjiniya kuti vatarise pane zvinotevera.

1. Mutoro wehurongwa chii?

Mutoro wesystem unosanganisira mutoro usingachinji uye mutoro unoshanduka, uye kazhinji saizi yemutoro ndiyo inosarudza saizi yekutanga yemota.

Mutoro usingachinji: simba guru rinogona kudziviswa ne screw kana yamira.

Kurema kunochinja: simba guru rinogona kumiriswa nesikuruu kana ichifamba.

2. Ndeipi kumhanya kwemota kwakanangana?

Kumhanya kwemota ine mutsara kwakabatana zvakanyanya ne lead ye screw, kutenderera kamwe chete kwe screw ndiko lead imwe ye nati. Kana uchimhanya zvishoma, zvinokurudzirwa kusarudza screw ine lead diki, uye kana uchimhanya zvakanyanya, zvinokurudzirwa kusarudza screw yakakura.

3. Chii chinodiwa kuti hurongwa huve hwakarurama?

Kururama kwescrew: kururama kwescrew kunowanzoonekwa nekururama kwemutsara, kureva kukanganisa pakati pekufamba chaiko nekufamba kwedzidziso mushure mekunge screw yatenderera kuita denderedzwa rakaoma rinovava.

Kurongeka kwenzvimbo yakadzokororwa: kurongeka kwenzvimbo yakadzokororwa kunotsanangurwa sekururama kwesisitimu kuti ikwanise kusvika panzvimbo yakatarwa kakawanda, inova chiratidzo chakakosha kune sisitimu.

Kudzoreredza shure: kudzoreredza shure kwe screw ne nati pakuzorora kana huwandu hwe axial hunogona kutamiswa. Sezvo nguva yekushanda ichiwedzera, kudzoreredza shure kuchawedzerawo nekuda kwekusakara. Kuripa kana kugadzirisa kudzoreredza shure kunogona kuitwa ne backlash elimination nut. Kana zvichidikanwa kuti pave ne bi-directional positioning, backlash inyaya.

4. Zvimwe zvasarudzo

Nyaya dzinotevera dzinofanirawo kutariswa pakusarudza: Kuisa mota ye stepper ine linear zvinoenderana nekugadzirwa kwemuchina here? Uchabatanidza sei chinhu chinofamba ne nati? Ndeipi nzira inoshanda yekurova screw rod? Ndeipi nzira yekufambisa ichaenderana nayo?

Nguva yekutumira: Mbudzi-16-2022